The common idea of air compressors is that they are used to inflate tires with air pressure, but they do more than that. Professionals in the construction industry use air compressors to provide effective compressed air to power tools. You can easily see it used in refrigerators, air conditioners, motorcycles, etc. Because of their large-scale use, companies that produce air compressors in India and around the world have come up with better, higher-end products.

Compressors convert gaseous energy into kinetic form by simply compressing and pressurizing the air. Next, air can flow with a sudden burst. Air is stored in the compressor tank, making the process easier to manage. Due to its portability, people use it to inflate the tires of their vehicles with air whenever they need it.

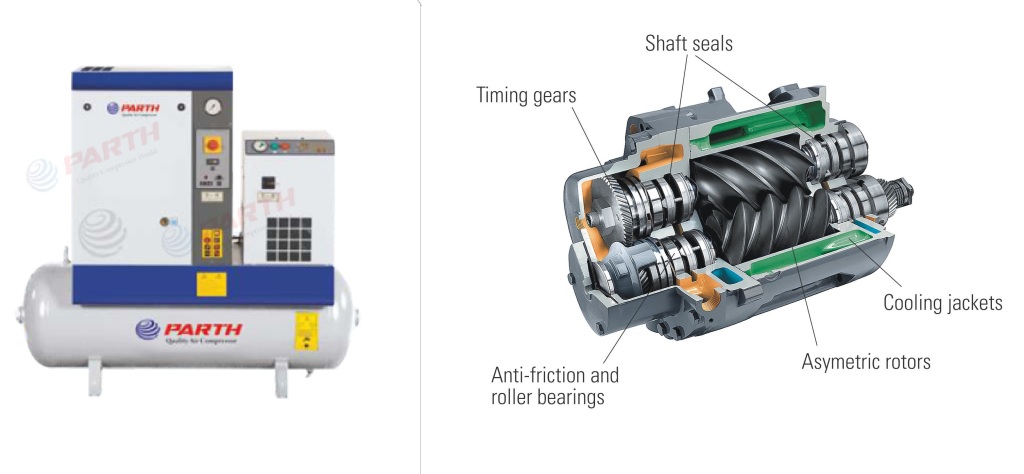

There are two ways to compress air. They are either through negative displacement or positive displacement. The main components of the compressor include the air filter. The filter removes dust and dirt after compaction is complete. A piston used in a compressor pumps air to a specific point. The three basic compressors types are rotary, centrifugal and reciprocating. Further classifications are based on various other characteristics such as phases, cooling based and lubrication.

Compressors can be single or multi stage depending on the stages. In single-stage compressors, a single cylinder delivers air directly to the storage tank. On the other hand, Multistage uses multiple cylinders for the same operation. A single stage is valuable for small jobs. Industrial applications with heavy machinery require a multi-stage high pressure air compressor for high pressure application.

Oil-free air compressors are mainly used for small household operations. As the name suggests, it does not require oil to operate, and the screw acts as a compression. Among them, the rotary type is preferred. The oil-free type prevents oil spillage and grease normally caused by the compressor. The only drawback is that it cannot handle the great pressures that oil types can easily do. They are easy to handle and cheap in your pocket.

The compact and portable forms of the compressors are meant for personal use. There are many factors need to be considered before buying one. Factors such as horsepower capacity, quality performance, durability, and operation and maintenance costs. Durability requires special attention as long life is essential in all industrial applications. The cast iron cylinders type used in compressors improves durability. Robustness is improved by regular oil lubrication. Make sure the strength of the compressor meets your requirements.

There are many listings of companies manufacturing air compressors in India. A little research and knowledge will help you choose a good product.

Parth Air Compressor, India’s leading manufacturer of air compressors with extensive field experience, provides high quality High Pressure Air Compressors for all your needs.

You must be logged in to post a comment.